Many ideas are born out of small chance…

In 1981, AF Azevedos was founded, the company that created the brand Bplan. A AF Azevedos, a company with over 40 years’ experience in the metalworking sector, began its activity with the production of molds, dies and cutters. He later expanded his business to sheet metal processing and the construction of electromechanical machines.

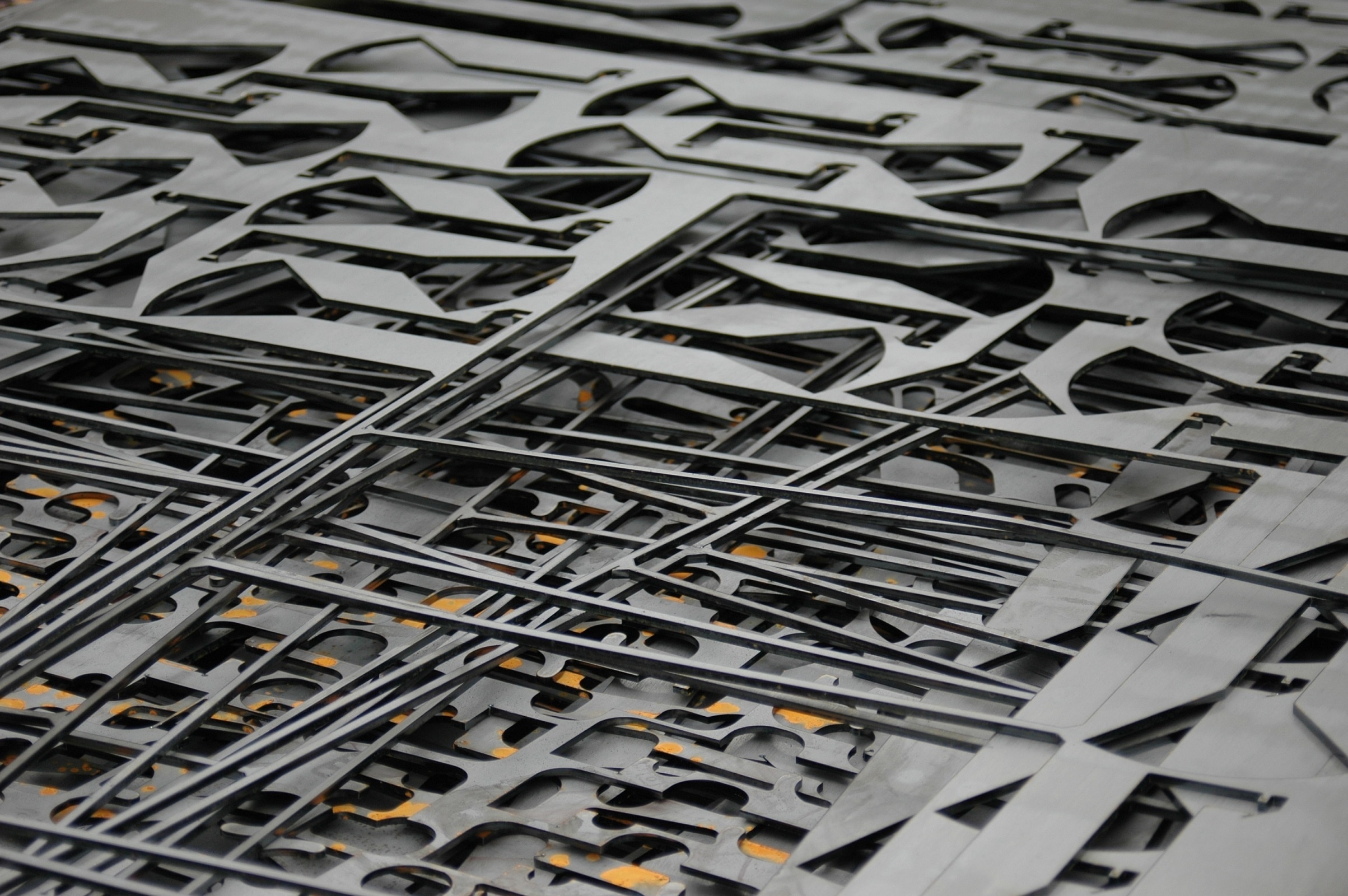

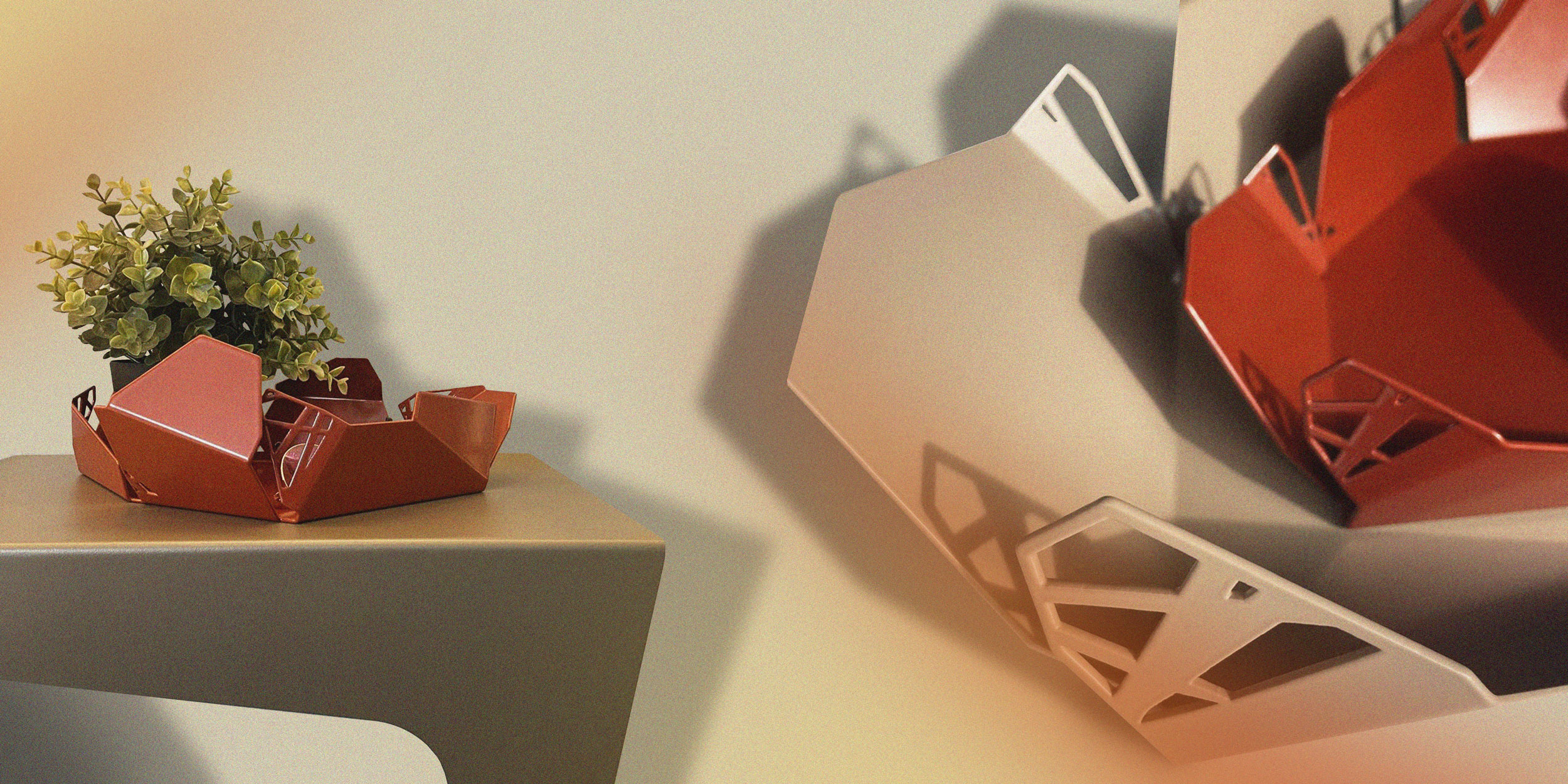

In the leftover material from AF Azevedos’ production, particularly from laser cutting, patterns and shapes appeared that aroused the interest of the company’s managers… The potential and formal richness of that material, whose useful life was coming to an end and from which new products could be born, was noticed… and so Bplan was born.

In 2014, AF Azevedos decided to move to Rua dos Perdões, in Vila Nova de Famalicão.

With 5 years of existence, Bplan began to explore its potential, taking part in national and international fairs..

In line with market demands, AF Azevedos expanded its production capacity and moved premises again, remaining in Rua Senhor dos Perdões.

In 2021, Bplan, already with over 10 years of experience in the development and production of unique metal solutions, decides to explore once again the potential of metal and invest in a new field of action – the creation of its own design product, ready to integrate a space. As a result of this creation and already having some presence in marketplaces, Bplan decided to invest in a new touchpoint and create its own e-commerce platform. So far, we’ve made all your new creations available online, simply and efficiently.

“We inspire people and differentiate spaces through the perfect combination of the versatility of metal and the creative skills of human beings.”

WHO ARE WE?

A specialized team, made up of technicians, engineers, architects and designers, who invest daily in monitoring and satisfying our clients’ needs.

With a focus on developing projects with an identity and their respective production, we promote the versatility and creativity of metal in Architecture, Design, Construction and Decoration, both nationally and internationally.

WE VALUE:

OUR CUSTOMERS’ SATISFACTION

We guarantee an offer that meets our customers’ preferences.

QUALITY OF OUR SOLUTIONS

We invest in a quality offer, complying with the applicable regulations and standards.

CREATIVE THINKING

We continually invest in diversifying our products and services, so that metal takes on shapes, colors and textures, where creativity is the limit.

SUSTAINABILITY

During product development, we always keep sustainability factors in mind, particularly in terms of packaging and transportation.

Keep in touch at

!

Subscribe to our newsletter here.