Our services

Our production area, located in Vila Nova de Famalicão, is used to carry out a wide range of metalworking services, following the applicable quality standards (ISO 9001:2015).

Total production area:

(1) Project

Transforming an idea into planning and technical preparation for execution.

(2) Workshop

3D modeling, CNC machining, electro erosion, turning, milling and grinding.

(3) Laser cutting

Cutting metal elements using a high-precision laser beam.

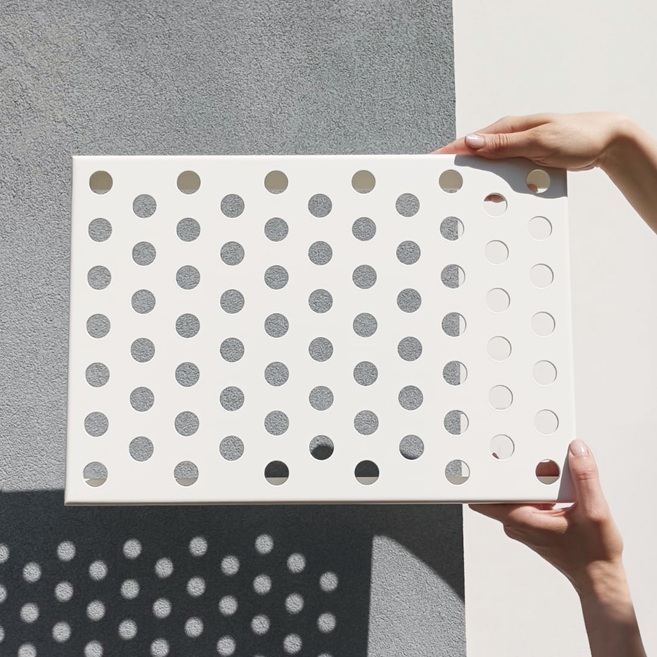

(4) Punching

Punching or cutting out specific shapes using a punch/die.

(5) Sanding

Improvement and surface treatment for subsequent finishing.

(6) Bending

Bending sheet metal into specific angles and shapes (e.g. flaps, corners…)

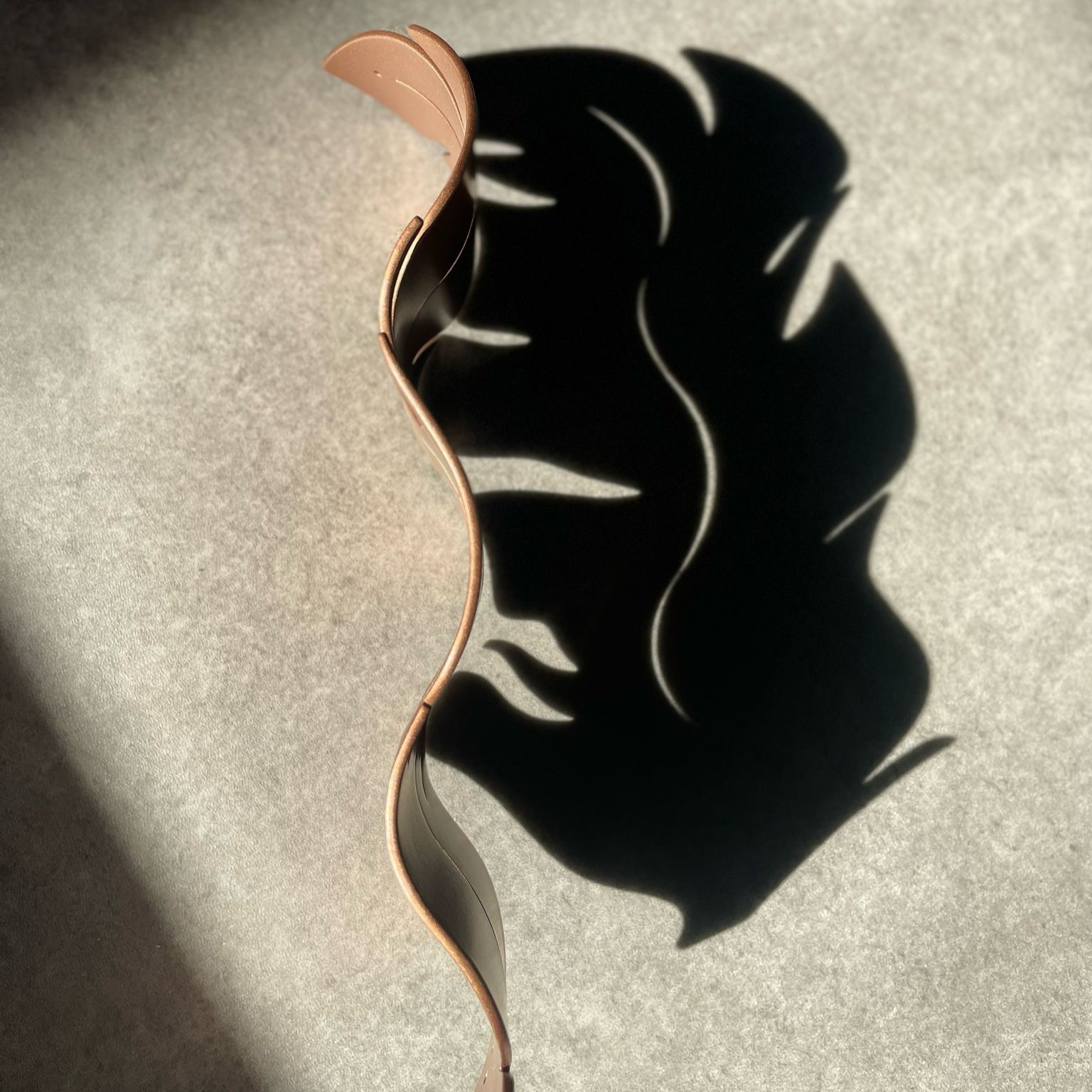

(7) Calendering

Attributing curvature and/or waviness to a metal sheet.

(8) Assembly

Joining components and installing the final product.

(9) Welding

Manual and/or robotic joining of metals in a permanent, structurally sound way.

(10) Thermolacquering

Painting and protecting metal surfaces with thermosetting powder paint.

Tailor-made solutions

Regardless of the scale of the project

We bring your ideas to life with a wide range of colors, shapes and textures, from small decorative objects to larger façades. Every detail is thought out to create spaces with an identity, marked by their versatility and innovation.

Dimensions

of the panels

Maximum: 2000 x 4000 mm

(without bending)

Materials and thicknesses

Steel and stainless steel (up to 25 mm)

Aluminum (up to 20 mm)

Copper and brass (up to 10 mm)

Among others (…)

Surface finish

Any RAL or Interpon color, with a matt, glossy, textured or metallic pigmented finish.

As for stainless steel, it can be polished or brushed.

Designs and Patterns

Let yourself be inspired by our catalog or create your own pattern. Just send us an image or drawing of the pattern you want and together we’ll turn your idea into reality.

Step by step,

we create successful projects:

The proposal is free and without obligation.

In person, online or by telephone, to clarify questions and analyze the feasibility of the project.

Collection of technical elements (plans, photographs…).

Sending the solution proposal and corresponding quote.

Development of physical samples for aesthetic or functional validation.

Once the proposal has been validated, production begins at in accordance with the applicable quality standards (ISO 9001).

It can be provided by Bplan or coordinated with local partners.

After your purchase, we will be happy to answer any questions you may have.

What our customers say about us:

Keep in touch at

!

Subscribe to our newsletter here.